Meccano Compatibility Guide

Almost every Meccano builder reaches the same moment sooner or later. The table is covered in parts from different boxes, sometimes from different years, and one simple question appears.

Will these parts actually work together?

Compatibility is the quiet backbone of every satisfying Meccano build. When it works, creativity flows naturally. When it doesn’t, even the best ideas fall apart into loose joints, misaligned gears, and endless rebuilding.

This guide exists to remove that frustration. It explains how Meccano compatibility really works, what mixes well, what doesn’t, and how to build with confidence instead of guesswork.

Why Compatibility Matters More Than Most Builders Expect

When people talk about compatibility, they often mean one simple thing: whether two parts can physically connect. In Meccano, that question is only the beginning.

True compatibility includes strength, alignment, weight distribution, material behavior, and how forces travel through a structure once motion is introduced. A beam can bolt on perfectly and still create problems later. A gear can mesh smoothly and still introduce friction a motor cannot overcome.

Builders who understand compatibility early approach Meccano differently. Instead of forcing ideas to work, they design with the system in mind. The result is fewer rebuilds, stronger models, and a building experience that feels rewarding instead of frustrating.

What Compatibility Really Means in the Meccano World

In the Meccano world, compatibility is not a yes-or-no question. It is a relationship between parts, materials, and forces. Two components might connect perfectly on the table and still fail once movement, weight, or vibration enters the picture.

This is because Meccano is closer to real engineering than many construction toys. Bolted connections transfer load. Axles experience torsion. Gears amplify resistance. When compatibility is right, these forces balance naturally. When it is wrong, problems appear quickly and repeatedly.

Experienced builders often describe compatibility as something you can feel. A compatible build feels calm and predictable. Adjustments improve behavior instead of introducing new issues. An incompatible build constantly fights back, even when it looks correct.

Once you adopt this mindset, Meccano becomes far more enjoyable. You stop chasing fixes and start designing with intention. That shift alone dramatically improves build quality and long-term satisfaction.

Classic Metal Meccano: Why It Remains the Gold Standard

Classic metal Meccano has survived for generations because its core logic works. Hole spacing, bolt sizes, and structural geometry have remained remarkably consistent. This consistency allows builders to combine parts from different eras without worrying about unexpected incompatibilities.

Metal also behaves honestly. When a structure flexes, you can see it. When a bolt loosens, you feel it. Nothing is hidden behind snap-fit tolerances or flexible connectors. This transparency makes problem-solving intuitive instead of frustrating.

For builders who plan to expand gradually, metal Meccano offers unmatched long-term compatibility. A collection grows organically instead of becoming outdated. Parts purchased today will still matter years from now.

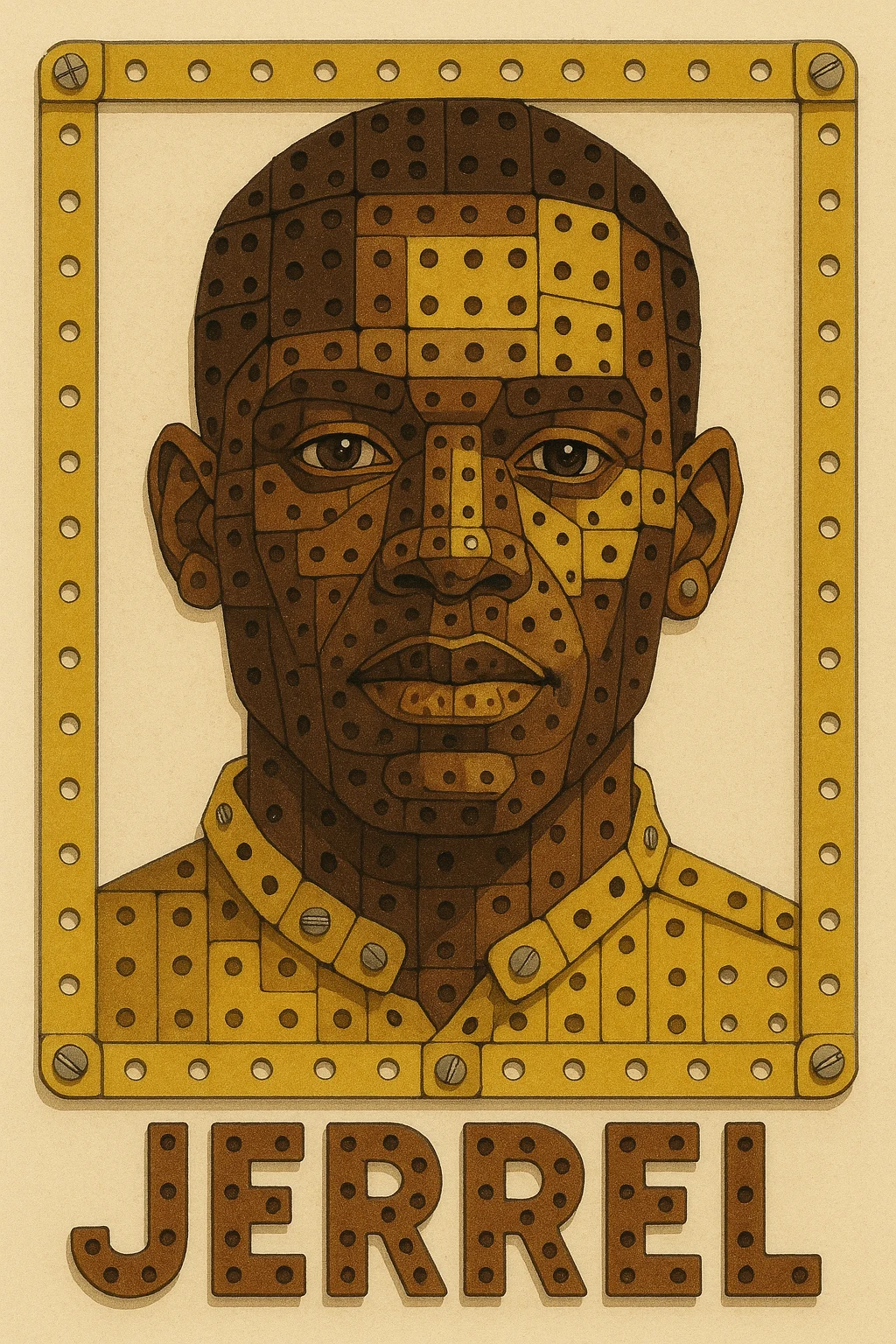

Jerrel’s Builder Insight

One of the most common mistakes I see is builders blaming themselves when a model doesn’t behave as expected. In many cases, the issue isn’t skill — it’s compatibility.

When parts naturally work together, a build almost guides you. When compatibility is forced, every step feels like a struggle. Learning to recognize that difference is one of the most valuable Meccano skills you can develop.

Modern Plastic Meccano: Faster Builds, Different Rules

Modern Meccano introduced plastic components to lower the barrier to entry. Snap-fit frames and molded connectors make early success faster, especially for younger builders or casual projects.

Within the modern plastic ecosystem, compatibility is strong. Sets are designed to work together visually and mechanically. Problems usually appear when plastic parts are mixed with classic metal without considering their different material behavior.

Plastic flexes. That flexibility absorbs vibration but also stores tension. Under load, plastic structures can slowly shift, changing alignment and increasing friction. This isn’t a flaw — it’s simply a characteristic of the material.

Builders who respect these differences get excellent results. Those who ignore them often experience instability and rapid wear.

Compatibility Comparison Overview

| System | Material | Compatibility Strength | Best For |

|---|---|---|---|

| Meccano | Metal & Plastic | Very high within system | Engineering realism |

| LEGO Technic | Plastic | High within Technic | Precision mechanics |

| K’NEX | Plastic rods | Medium | Large structures |

Compatibility at a Glance

If you want a fast answer before starting a build, this table summarizes what works well, what requires caution, and what should be avoided entirely.

| Combination | Compatibility Result |

|---|---|

| Metal Meccano + Metal Meccano | Excellent — fully compatible across generations |

| Modern Plastic + Modern Plastic | Very good — designed to work together |

| Metal + Modern Plastic | Possible — light loads only |

| Meccano Junior + Standard Meccano | Not recommended |

| Meccano + LEGO Technic | Rarely practical beyond experiments |

| Meccano + K’NEX | Structurally weak under load |

Seeing Compatibility Differences in Action

Reading about compatibility is useful, but watching different construction systems perform side by side makes the differences immediately clear. Movement, stability, and load handling reveal far more than static photos ever could.

In this comparison, similar buggy-style builds are tested using different construction philosophies. What looks comparable at first quickly behaves very differently once motors, weight, and friction enter the picture.

Pay attention to how smoothly each model accelerates, how well it maintains alignment under stress, and how predictable the movement feels. These are the same signals you’ll notice when working with mixed parts at home.

Meccano Compatibility — Frequently Asked Questions

These are the questions I get most often from builders who are expanding their Meccano collections or trying to combine parts from different sets. The answers are based on real-world building experience, not theory.

In most cases, yes — especially when you are working with classic metal Meccano. Hole spacing and bolt sizes have remained consistent for decades, which is why older metal parts usually integrate smoothly with newer ones.

Small cosmetic differences may exist, but structurally the system remains highly compatible. This long-term consistency is one of Meccano’s biggest strengths.

Meccano Junior is designed for a completely different purpose. Parts are larger, connections are reinforced, and tolerances are optimized for younger builders rather than mechanical precision.

Mixing Junior parts with standard Meccano often leads to loose joints and unstable structures. This separation is intentional and helps each system work better at its intended level.

While it is sometimes physically possible, mixing Meccano with LEGO Technic rarely works well in practice. The two systems are built around very different engineering philosophies.

LEGO Technic favors lightweight precision, while Meccano emphasizes rigidity and load-bearing strength. Once motors or gears are involved, those differences quickly become a problem.

This is one of the most common compatibility mistakes. Motors are tuned for the systems they are designed for. Using motors across brands often results in poor torque, excessive vibration, or premature wear.

For reliable motorized builds, it’s best to stay within one ecosystem, especially when load-bearing movement is involved.

This usually indicates a compatibility issue rather than a building mistake. Misalignment, uneven load distribution, or mixed materials often cause friction and instability that isn’t visible at first.

When a build constantly needs adjustment, it’s often a sign that parts are being forced to work together instead of cooperating naturally.

Expand slowly and deliberately. Learn how one system behaves before adding new parts or motors. This approach leads to stronger builds and far fewer compatibility frustrations.

Builders who rush expansion often spend more time fixing problems than actually enjoying the build.

Build Smarter — Not Harder

Compatibility isn’t about owning more parts. It’s about understanding how systems are designed to work together. Once you respect that logic, Meccano becomes less frustrating and far more rewarding.

Start with a solid foundation, expand with intention, and every build will feel stronger, smoother, and more satisfying from the first bolt to the final movement.

2 comments

[…] Meccano Picks Meccano Troubleshooting: Fix Motors, Builds & Common Problems Meccano Compatibility Explained: What Actually Fits and What… Meccano Junior Insect Mania Review: Best Toolbox for… Meccano MeccaSpider Review: Creepy […]

[…] Same Roots, Very Different… Meccano Troubleshooting: Fix Motors, Builds & Common Problems Meccano Compatibility Explained: What Actually Fits and What… Meccano Junior Insect Mania Review: Best Toolbox for… Meccano MeccaSpider Review: Creepy […]