Meccano Troubleshooting Guide: Why Builds Fail — and How to Fix Them

Motors stall. Structures wobble. Bluetooth refuses to connect. This guide explains what’s really happening and how to fix it properly.

Why Problem-Solving Posts Matter More Than Reviews

Reviews help you decide what to buy. Problem-solving guides help you enjoy what you already own.

Builders searching for fixes are not casual readers. They are invested. They are frustrated. And they are willing to read carefully if the information actually helps.

That’s why troubleshooting content tends to outperform flashy list articles over time. It answers real questions that don’t disappear when trends change.

If you’re still unsure how different sets interact, start with the Meccano Compatibility Guide. Many problems begin there.

Why Your Meccano Motor Isn’t Working (Fixes That Actually Help)

When a motor fails, it’s tempting to assume it’s defective. In reality, most Meccano motors are far tougher than they look. They stop working because something around them is wrong.

The most common causes

- Gears mounted slightly off-axis

- Too much resistance for the motor’s torque

- Battery voltage dropping under load

- Friction caused by misaligned frames

A useful rule of thumb: motors don’t hide mistakes. They amplify them.

Robotic sets like the Meccano MeccaSpider make this especially obvious. A tiny alignment error can completely change how the robot behaves.

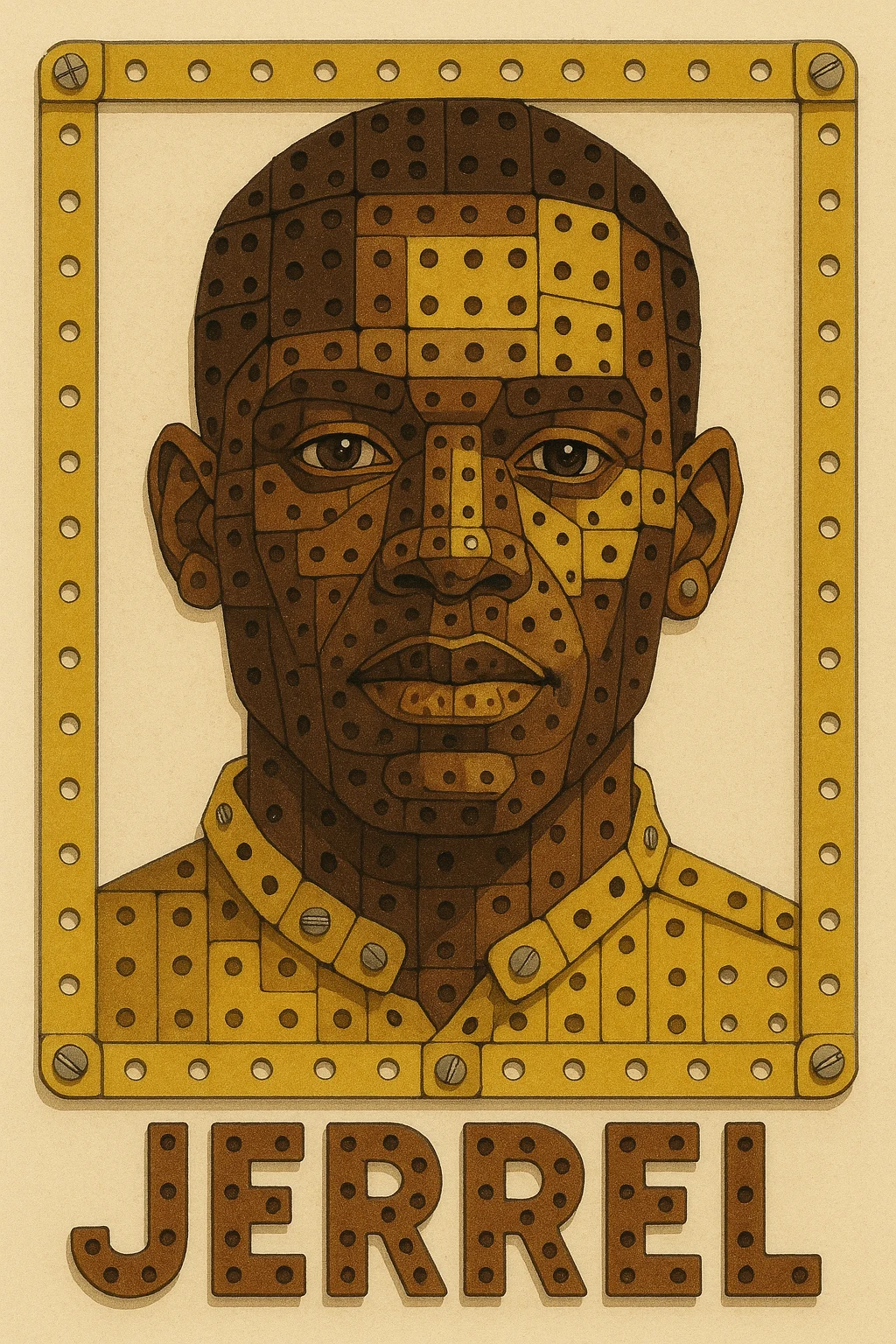

Meccanoid Robot Repair Example

Common Meccano Building Mistakes (And How to Avoid Them)

Many unstable builds fail for the same few reasons. They look impressive on the table, but lack the mechanical fundamentals needed for movement.

Structural mistakes that cause failures

- Long spans without cross-bracing

- Single-bolt joints under heavy load

- Stacking flexibility instead of rigidity

- Ignoring torsion forces

Meccano behaves much closer to real engineering than many toy systems. Gravity, leverage, and vibration always win.

Builders coming from LEGO often notice this immediately. Precision matters more, and shortcuts are punished. Sets like the STEM 2-in-1 RC Construction Truck are excellent teachers because mistakes show up instantly.

Why Builds Fall Apart Once You Add Movement

Static builds can hide weaknesses. The moment motors, gears, or weight are introduced, those weaknesses become impossible to ignore.

Movement adds vibration, torque, and changing load paths. These forces travel through the entire structure, searching for the weakest point.

Reinforcing joints, doubling connection points, and shortening lever arms often fixes problems immediately. These are not cosmetic changes — they are structural.

Bluetooth and Smart Control Problems Explained

Bluetooth issues are often blamed on apps or firmware. In practice, power delivery is the real culprit.

- Low battery voltage causes unstable connections

- Motors draw current away from control modules

- Loose wiring breaks continuity during movement

Smart Meccano sets expect stable power. Once motors start pulling current, weak batteries or poor wiring quickly reveal themselves.

Bluetooth Not Working on Meccano Set 10 (19605)

When to Fix a Build — and When to Rebuild It

One of the hardest lessons for builders is knowing when to stop fixing. Some problems are symptoms of deeper design flaws.

If you’re constantly tightening bolts, adjusting gears, and chasing the same issues, a partial rebuild is often faster and more satisfying.

Rebuilding isn’t failure. It’s how real engineering improves over time.

Final Thoughts: Meccano Rewards Understanding

Meccano does not reward rushing. It rewards observation, correction, and patience.

Builders who learn to troubleshoot instead of forcing solutions end up with stronger models and far more enjoyment.

If you like solving problems rather than avoiding them, Meccano becomes one of the most rewarding construction systems available.

Frequently Asked Meccano Troubleshooting Questions

This almost always points to mechanical resistance. Misaligned gears, bent axles, or uneven frame mounting can introduce friction that a free-spinning test doesn’t reveal.

If the motor spins freely when disconnected, the motor is healthy — the structure needs adjustment.

Tight enough to remove play, but not so tight that parts bind. Over-tightening can distort frames and increase friction, especially around moving joints.

Motors introduce torque and vibration. Weak joints that survive static builds often fail under motion. Reinforce load-bearing points and shorten lever arms.

Yes — and it’s one of the most common causes. When motors draw current, voltage drops can disrupt Bluetooth communication before anything fully shuts down.

Often, yes. If the same problem keeps returning, the underlying structure likely needs redesign. Rebuilding usually saves time in the long run.

1 comment

[…] Engineering Kits for Adults – 2026 Erector Set vs Meccano: Same Roots, Very Different… Meccano Troubleshooting: Fix Motors, Builds & Common Problems Meccano Compatibility Explained: What Actually Fits and What… Meccano Junior Insect Mania […]